Editor's note:Traditional arts and crafts are supreme samples of Chinese cultural heritage. China Daily is running this series to show how master artisans are using dedication and innovation to inject new life into heritage. In this installment, we find out why the Four Treasures of the Study are not merely tools used by literati but also carriers of Chinese heritage.

A short soft brush connected to a long hard handle, both vigorous and gentle—a simple Chinese writing brush can describe the most sophisticated idea. Achieving both technical excellence and spiritual freedom in writing, a good brush allows for unrestrained creativity and endless variation.

A brush can reveal a dot, a line, the sun, the moon, mountains, rivers, wind and everything people can sense in the world, slender or thick, big or small, concrete or abstract.

Perhaps it is one of the few tools invented by humans that is so practical yet so rich in symbolic meanings over millennia. It not only conveyed common people's care and emotions, but also recorded history, narrated thoughts, and created the most refined art and literature of this culture, thus greatly influencing the development path of Chinese civilization.

In his book Huzhou Writing Brush and Chinese Culture published by Peking University Press in 2010, scholar Ma Qingyun quotes Zhou Ruchang(1918-2012), a prestigious scholar, poet and calligrapher, as saying that:"Without the writing brush, Chinese characters could not have undergone their evolution, not to mention the painting art. Their forms, structures, writing methods, functions and artistic effects would not have arrived at the current situation. Ultimately, the writing brush determines the various forms of documents, such as scrolls, books, records, letters and files. "

Ma says:"For Zhou, the spiritual essence of Chinese culture is manifested in the writing brush, and its development depends on the writing brush as well. "

For him, the diverse temperaments, personalities, wills, spiritual worlds, attitudes toward life, external grace, internal beauty, and cultivation of the Chinese people all flow from the tip of that brush, Ma says.

"So, the writing brush is not only a representative of Chinese culture, but also the creator of Chinese culture, "he adds.

Sitting in front of a water basin, an artisan engages in the washing, sorting, combing and shaping of the wool. [Photo by Yang Yang/China Daily]

Supple fur

Legend has it that one day in 223 BC, as Meng Tian, a great general of the Qin state, who later oversaw the construction of the Great Wall, was out hunting. At some point, he saw the tail of an unlucky hare had left a trail of blood on the ground, which inspired him to make the first Chinese writing brush in history.

Meng first got some hare fur, inserted it into a bamboo stick, and tried to use it to write. However, the fur of the hare was so sleek that the brush failed to absorb ink. After trying several times in vain, he casually threw the brush into a lime pit outside a window.

Several days later, Meng came across the abandoned brush and picked it up, finding that the fur had become supple. He dipped it into ink and wrote several characters very smoothly. Unintentionally, the lime wash had degreased the fur. Lime is still applied today.

In another version of the legend, instead of hare fur and bamboo stick, Meng used a wooden stick, harder deer fur in the middle and softer goat wool on the outside, a method also still employed today.

Archaeological discoveries have long refuted the legends about Meng inventing the Chinese writing brush.

Archaeological evidence shows that more than 6, 000 years ago, people living in the Banpo site, 10 kilometers east of today's Xi'an, Shaanxi province, used brushes to draw patterns and lines on the surface of pottery. However, compared with pottery or oracle bones, brushes are difficult to preserve and thus rarely seen in ancient ruins.

In the following thousands of years before Meng's time, brush traces are also shown on the oracle bones and pottery from the Shang Dynasty(c. 16th century-11th century BC). It is believed that the inscriptions were engraved on the oracle bones after being written with a brush. Among the inscriptions, there is a character, yu, that means a writing brush. It vividly depicts a hand holding a brush.

In the late 1950s, archaeologists unearthed a writing brush in Xinyang of Henan province. Dating to the early Warring States Period(475-221 BC), this brush is the oldest one ever discovered in China, much earlier than Meng's mythical"invention".

In another tomb of the middle Warring States Period discovered in Changsha, Hunan province, a writing brush made of good-quality hare fur and an 18. 5-centimeter bamboo handle was found. The brush tip was 2. 5 cm long. It was an epitome of the writing tool in early times.

In the next more than 2, 000 years, writing brushes underwent a significant evolution alongside the advancement of writing mediums—from oracle bones, bamboo slips and silk to different types of paper. Also, changes in writing postures due to the increase in furniture height, especially starting from the Song Dynasty(960-1279), and the growth of distinct schools of painting and calligraphy all played pivotal roles in shaping the evolution of writing brushes.

In the vicissitudes of history, the center for making top-quality writing brushes shifted from one place to another. Before the Yuan Dynasty(1271-1368), the most refined writing brushes, usually made of hare fur, were produced in Xuancheng of today's Anhui province, although there were also brush makers in other places like Huzhou in today's Zhejiang province.

As the Northern Song period(960-1127)collapsed, the court of the Southern Song period(1127-1279)moved its capital to Lin'an, known today as Hangzhou, Zhejiang province. Subsequently, a significant influx of writing brush artisans migrated to Huzhou, a neighboring city of Hangzhou, which already housed numerous brush makers.

Since the Yuan Dynasty, Huzhou writing brushes have supplanted those crafted in Xuancheng, establishing themselves as the premier writing tool in China. During the Ming(1368-1644)and Qing(1644-1911)dynasties, Huzhou writing brushes were esteemed to such an extent that they were presented to the emperors as tributes.

Huzhou writing brushes are distinguished by their sharpness, neatness, and durability. Structurally, the brush should be well-built, featuring resilient bristles that swiftly regain their original shape after compression.

However, in the latter half of the last century, with the widespread adoption of modern pens, writing brushes began to recede from their long-standing prominence. In an effort to safeguard this ancient craft, the artistry of the Huzhou writing brushes was designated as a form of national intangible cultural heritage in 2006.

Yang Wen, 30, hones his skills under the instruction of Qiu Changming, 74, a national inheritor of the Huzhou writing brush craftsmanship. [Photo by Yang Yang/China Daily]

Perfecting the craft

The complete crafting process of a Huzhou writing brush comprises eight procedures, meticulously subdivided into 128 steps, according to Qiu Changming, a national-level inheritor of the craftsmanship.

The 74-year-old is one of the writing brush master artisans in Shanlian town of Huzhou.

Artisans in the town have worshipped General Meng as the forefather of the writing brush for thousands of years. While Meng seemingly didn't actually invent the brush, he is still believed to have, in reality, improved the materials and techniques used to produce it, Qiu says.

Over generations, artisans in Huzhou have continuously honed their craft, driven by the patronage of esteemed calligraphers like Wang Xizhi and Wang Xianzhi during the Eastern Jin Dynasty(317-420), as well as literary figures, such as Du Mu in the Tang Dynasty(618-907)and Su Shi in the Song Dynasty, all of whom once worked in this region.

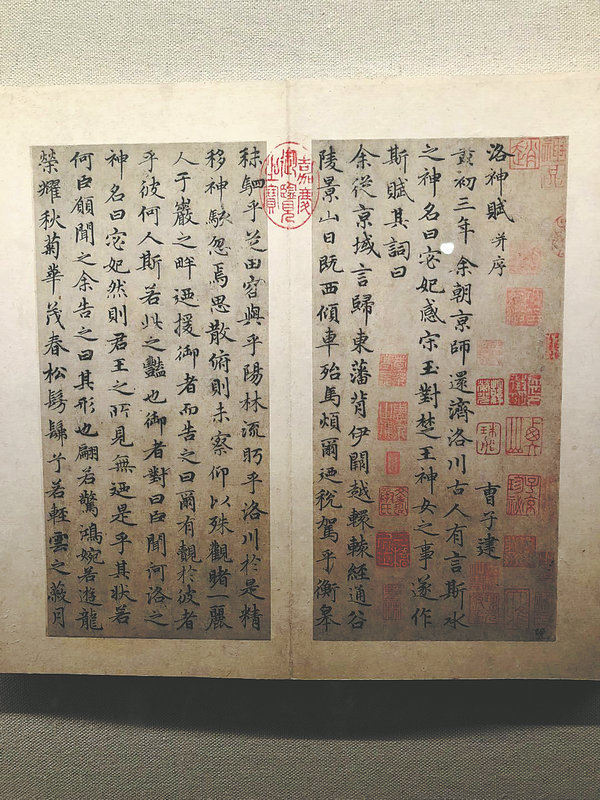

An iconic work by Zhao Mengfu, a Yuan Dynasty(1271-1368)calligrapher, on display at Beijing's Palace Museum. [Photo by Mi Jiafeng/China Daily]

The pinnacle of demand arrived with the renowned calligrapher Zhao Mengfu, a native of Huzhou, during the end of the Song and the start of the Yuan.

Zhao, who's known for his unwavering dedication, was reputed to inscribe 10, 000 characters daily over a remarkable span of 60 years. Echoing the wisdom of Confucius that emphasizes the importance of tool preparation for excellence in work, Zhao carefully attended to his brushes, frequently commissioning artisans for their maintenance. To meet his standard, artisans needed to choose the best fur from 10 good brushes to make just one.

"Now, similarly, we can pick only one qualified strand from thousands, which shows the fineness of our craft, "Qiu says.

In 1966, at age 16, Qiu, who came from a poor family, got the chance to work at the Shanlian Huzhou Ink Brush Factory as an apprentice to master Yao Guanqing.

Yao was born at the end of the Qing Dynasty and trained to be a writing brush artisan.

Since the Yuan Dynasty, the Huzhou writing brush had garnered acclaim from successive generations of literati. Following centuries of development, a cadre of artisans specializing in crafting Huzhou brushes was established in Shanlian.

During the 1910s, the small town saw more than 1, 000 artisans work in more than 300 family workshops. Some artisans went to Suzhou, Shanghai and Beijing to make and sell writing brushes, and Yao was one of them. After 1949, he returned to Shanlian and worked in family workshops.

In 1956, the Shanlian Huzhou Ink Brush Factory was established, and Yao and other 600 brush makers were recruited. At that time, masters were apprehensive about taking apprentices. All his life, Yao had only one apprentice, Qiu.

It takes 25 to 30 days to make a Huzhou writing brush. [Photo by Yang Yang/China Daily]

It takes 25 to 30 days to make a Huzhou writing brush at the factory, depending on the weather. Among the eight major procedures, the most important two are those completed in a water basin usually by woman artisans, and polishing, a step usually done by men. Qiu's job is polishing.

A traditional Huzhou writing brush typically comprises a brush made of goat wool and a handle made of bamboo.

"If you put a strand of goat wool under a microscope, you will see the tiny pores on it. That's why goat wool brushes can absorb the most ink compared with brushes made of hare fur or yellow weasel fur, "Qiu says. "So it is better to write big characters on wide paper, a fashion popular among calligraphers in later times, especially during the Qing Dynasty. "

What is most special about the Huzhou brush lies in its tip. The longer and the more transparent the tip is, the better the brush, Qiu says.

A brush with a fine tip, when pressed, sees its strands spread out fully and neatly. During writing, the ink flows evenly and smoothly. After lifting the brush, the tip returns to its original conical shape without splitting. A fine-tip brush is also durable and long-lasting.

In ancient times, goats raised in Huzhou ate not only grass but also mulberry leaves in winter, so their wool contained more protein compared with goats in other places. But now people in Huzhou do not raise such goats, so the factory purchases goat wool from Nantong in Jiangsu province.

But each goat can only provide 150 grams of wool and only a third of it has a sharp tip. The selection of qualified strands relies on artisans'fine work in the water basin.

Wang Xiaohua, 60, a master artisan, shows one of the best writing brushes produced by the Shanlian Huzhou Ink Brush Factory. [Photo by Yang Yang/China Daily]

Right posture

Sitting in front of a plastic water basin in the Shanlian Huzhou Ink Brush Factory, 60-year-old Wang Xiaohua, wearing a pair of golden-rimmed presbyopic glasses, is deftly combing the small pile of wet goat wool with a bone comb in her right hand and aligning the tips, as she has done for the past 43 years. Wang Xiaohua is a provincial inheritor of Huzhou writing brush craftsmanship.

It is hard work.

"You have to sit sideways, leaning to the right as you need to transfer the strength from your whole body to your hands so that you can apply the strength deftly to avoid damaging the tips. Our hands need to be steady and strong. Besides, sitting like this won't block the natural light so that you can see the wool clearly. But sitting sideways for hours every day hurts our backs, "she says.

In winter, artisans have to dip their hands into cold water frequently, so that many of them suffer from chilblains and arthritis.

"Bone combs are very sharp. If not careful, you will puncture your other hand, "she says.

Wang Xiaohua grew up in the factory, since her parents worked there.

As a child, she found the woman artisans seemed happy as they talked to each other while finishing the work at hand easily. After graduating from senior middle school, she went to the factory, doing the same job as her mother did.

"Once I started, I found the work was not as easy as it looked, "she says.

However, peer pressure pushed Wang Xiaohua to work harder, and as she made progress, she gradually fell in love with it.

"It's just an ordinary job, a repetitive one, but after doing it for so many years, I found this seat here is the most reassuring place for me. I've spent more time here than at home. It has become an important part of my life, "she says.

When Wang Xiaohua fully mastered the skills, she understood more about writing brushes.

"It's not only a writing tool, but also closely connects with the entire history and culture of China, "she says.

"It also served as a cultural bridge in global exchanges in the 1980s and'90s. The writing brush perfectly showcases the wisdom of ancient Chinese people. "

In the water basin procedure, artisans dip wool in cold water, and after washing, sorting, combing and shaping, they process the wool into semifinished brushes.

Drying is one of the 128 steps in the crafting process of Huzhou writing brushes. [Photo by Yang Yang/China Daily]

After steps such as drying, bundling and inserting the brush into the hallowed end of a handle, it is Qiu's job to polish the brush, removing all substandard wool so that the brush becomes smooth and white.

The outline of a good brush should resemble that of a bamboo leaf or a bamboo shoot, depending on its size, Qiu says.

The key procedures require artisans to be extremely patient as they need to sit there for hours every day. "Not to mention that if you want to become an excellent artisan, you need to have an intuitive understanding of the work, "he says.

After a seven-year apprenticeship, Qiu was able to polish goat-wool brushes of all grades. In the 1980s, he started taking apprentices. However, as the work is hard and salary low, half of his apprentices quit. Even if his apprentices did the job until retirement, they did not take any apprentice themselves, he says.

At its peak time in the 1960s and'70s, the factory saw 500 to 600 artisans producing 1. 2 million writing brushes a year, most of which were exported to Japan, but now there are only 50 to 60 artisans, says 63-year-old Ma Zhiliang, head of the factory.

Now, few young people are willing to do the work, Qiu says, which is the major challenge they face about how to pass on this precious craft.

Yet, he sees hope in his apprentice, 30-year-old Yang Wen.

In September 2018, after graduating from university, Yang, who's from Gansu province, visited Shanlian, the hometown of his girlfriend, Yao Yulin. The trip kindled the young man's interest in the craft.

Besides, Yao Yulin's family owns a brush-making workshop, and her mother and grandmother are both artisans. At the suggestion of her father, the young couple decided to continue the family's brush-making business.

Later that year, after a traditional ceremony, Yang became Qiu's 11th apprentice.

"Now, the craftsmanship of Huzhou writing brushes has peaked. If we don't pass on our skills to the coming generations, the craft will not improve but only decline, "Qiu says.

In addition to taking apprentices, Wang Xiaohua says that they want to get the interest of more young people through livestreams and by holding events at schools.

In terms of innovating on writing brushes, she says they are trying to mix different materials to meet different writers'needs.

Besides, the factory has become a tourist attraction for people to learn how to make a brush by visiting the workshops and polishing brushes themselves. "Sometimes, we receive as many as 150 people at a time, "Wang Xiaohua says.